Product/Account Links

AMSOIL Accounts

Products

Other Products

AMSOIL OE 0W-16 Synthetic Motor Oil

Product Details

OE Synthetic Motor Oil is for mechanics and drivers seeking peace of mind protection and exceptional value in synthetic motor oil. It delivers 100 percent synthetic engine protection for advanced automotive technology, including turbochargers and direct injection. OE is specifically formulated for the longer drain intervals recommended by original equipment (OE) manufacturers.

Product Description

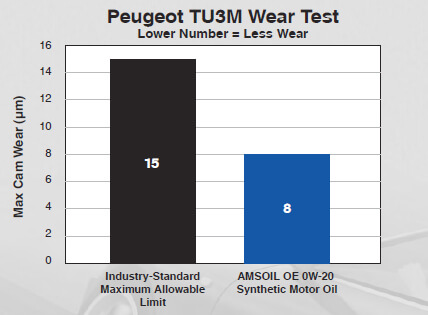

Provides Advanced Wear Protection

OE Synthetic Motor Oil provides excellent wear control and protects critical engine parts like pistons and cams. This added protection is particularly important in the extreme environments produced by today’s smaller displacement engines that often run lower viscosity oil. Camshaft wear can result in poor valve timing, greatly reducing engine efficiency and leading to expensive repairs. The Peugeot TU3M Wear Test (CEC L-38-A-94), which must be passed to meet the GM* dexos1® Gen 2 specification, determines a motor oil's ability to limit wear. For 100 hours the four-cylinder test engine is subjected to extreme, wear-inducing conditions. AMSOIL OE Motor Oil provided 47 percent more wear protection1 than required by the GM dexos1 Gen 2 specification.

OE Synthetic Motor Oil provides excellent wear control and protects critical engine parts like pistons and cams. This added protection is particularly important in the extreme environments produced by today’s smaller displacement engines that often run lower viscosity oil. Camshaft wear can result in poor valve timing, greatly reducing engine efficiency and leading to expensive repairs. The Peugeot TU3M Wear Test (CEC L-38-A-94), which must be passed to meet the GM* dexos1® Gen 2 specification, determines a motor oil's ability to limit wear. For 100 hours the four-cylinder test engine is subjected to extreme, wear-inducing conditions. AMSOIL OE Motor Oil provided 47 percent more wear protection1 than required by the GM dexos1 Gen 2 specification.

Protects Pistons from Low-Speed Pre-Ignition

OE Synthetic Motor Oil features unique chemistry proven to protect your engine against the harmful effects of low-speed pre-ignition (LSPI). LSPI is the spontaneous ignition of the fuel/air mixture prior to spark-triggered ignition. Most new engines feature gasoline direct injection (GDI), often coupled with a turbocharger. These technologies heighten the possibility of LSPI events, which can destroy pistons and connecting rods. A properly formulated motor oil is critical for protecting your engine against LSPI.

Original equipment manufacturers (OEMs) like GM have addressed the issue by designing tests to determine a motor oil's ability to prevent LSPI. OE Synthetic Motor Oil achieved 100 percent protection against LSPI2 in the engine test required by the GM dexos1 Gen 2 specification– zero occurrences were recorded throughout five consecutive tests.

Keeps Engines Clean

OE Synthetic Motor Oil has a 100 percent synthetic, pure chemical structure that is engineered to remove harmful contaminants. Its synthetic base oils naturally resist chemical breakdown to help prevent deposits. Its detergent and dispersant additives give OE excellent sludge and deposit fighting properties. OE Synthetic Motor Oil helps keep your engine clean, reliable and running at peak performance.

Protects in All Temperatures

Synthetic base oils and an advanced additive package make OE Synthetic Motor Oil ideal for today's hotter running engines. It effectively fights heat to control deposits, prevent thickening and limit oil consumption. OE's uniform structure keeps it fluid in low temperatures for easier cold starts and rapid lubrication of components to reduce start-up wear.

Improves Fuel Economy & Maintains Low Emissions

OE Synthetic Motor Oil is licensed by the American Petroleum Institute (API) to meet and exceed the requirements commonly found in owner's manuals. It excels in fuel-economy testing, earning the additional "Resource Conserving" designation from the API. OE is also friendly toward modern emissions-control systems, promoting proper operation of catalytic converters for optimum service life and low exhaust emissions.

1Based on independent testing of OE 0W-20 in the Peugeot TU3M Wear Test as required by the dexos1 Gen 2 specification.

2Based on zero LSPI events in five consecutive tests of AMSOIL OE 5W-30 Motor Oil in the LSPI engine test required by the GM dexos1 Gen 2 specification.

*All trademarked names are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim, express or implied, is made by their use.

APPLICATIONS

Use AMSOIL OE Synthetic Motor Oil in applications that require any of the following specifications:

0W-16 (OES)

API SN PLUS (Resource Conserving), SM...

COMPATIBILITY

AMSOIL OE Synthetic Motor Oil is compatible with other synthetic and conventional motor oils. Adding other oils, however, will shorten the life expectancy of AMSOIL motor oils and reduce their performance benefits. AMSOIL does not support extended drain intervals where oils have been mixed.

Aftermarket oil additives are not recommended for use with AMSOIL OE Synthetic Motor Oil.

TECHNICAL SERVICES

For immediate answers to your technical questions call (715) 399-TECH (8324) between 8 a.m. and 5 p.m. Central time or email tech@amsoil.com.

SERVICE LIFE

In gasoline-fueled vehicles, AMSOIL OE Synthetic Motor Oil is recommended for the intervals stated by the vehicle manufacturer or indicated by the oil life monitoring system. Change oil filter at every oil change.

OE Synthetic Motor Oil features unique chemistry proven to protect your engine against the harmful effects of low-speed pre-ignition (LSPI). LSPI is the spontaneous ignition of the fuel/air mixture prior to spark-triggered ignition. Most new engines feature gasoline direct injection (GDI), often coupled with a turbocharger. These technologies heighten the possibility of LSPI events, which can destroy pistons and connecting rods. A properly formulated motor oil is critical for protecting your engine against LSPI.

Original equipment manufacturers (OEMs) like GM have addressed the issue by designing tests to determine a motor oil's ability to prevent LSPI. OE Synthetic Motor Oil achieved 100 percent protection against LSPI2 in the engine test required by the GM dexos1 Gen 2 specification– zero occurrences were recorded throughout five consecutive tests.

Keeps Engines Clean

OE Synthetic Motor Oil has a 100 percent synthetic, pure chemical structure that is engineered to remove harmful contaminants. Its synthetic base oils naturally resist chemical breakdown to help prevent deposits. Its detergent and dispersant additives give OE excellent sludge and deposit fighting properties. OE Synthetic Motor Oil helps keep your engine clean, reliable and running at peak performance.

Protects in All Temperatures

Synthetic base oils and an advanced additive package make OE Synthetic Motor Oil ideal for today's hotter running engines. It effectively fights heat to control deposits, prevent thickening and limit oil consumption. OE's uniform structure keeps it fluid in low temperatures for easier cold starts and rapid lubrication of components to reduce start-up wear.

Improves Fuel Economy & Maintains Low Emissions

OE Synthetic Motor Oil is licensed by the American Petroleum Institute (API) to meet and exceed the requirements commonly found in owner's manuals. It excels in fuel-economy testing, earning the additional "Resource Conserving" designation from the API. OE is also friendly toward modern emissions-control systems, promoting proper operation of catalytic converters for optimum service life and low exhaust emissions.

1Based on independent testing of OE 0W-20 in the Peugeot TU3M Wear Test as required by the dexos1 Gen 2 specification.

2Based on zero LSPI events in five consecutive tests of AMSOIL OE 5W-30 Motor Oil in the LSPI engine test required by the GM dexos1 Gen 2 specification.

*All trademarked names are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim, express or implied, is made by their use.

APPLICATIONS

Use AMSOIL OE Synthetic Motor Oil in applications that require any of the following specifications:

0W-16 (OES)

API SN PLUS (Resource Conserving), SM...

COMPATIBILITY

AMSOIL OE Synthetic Motor Oil is compatible with other synthetic and conventional motor oils. Adding other oils, however, will shorten the life expectancy of AMSOIL motor oils and reduce their performance benefits. AMSOIL does not support extended drain intervals where oils have been mixed.

Aftermarket oil additives are not recommended for use with AMSOIL OE Synthetic Motor Oil.

TECHNICAL SERVICES

For immediate answers to your technical questions call (715) 399-TECH (8324) between 8 a.m. and 5 p.m. Central time or email tech@amsoil.com.

SERVICE LIFE

In gasoline-fueled vehicles, AMSOIL OE Synthetic Motor Oil is recommended for the intervals stated by the vehicle manufacturer or indicated by the oil life monitoring system. Change oil filter at every oil change.

Product Size

| Code | Package Size | Unit of Measure | Product |

|---|---|---|---|

| OESQT (OESQT-EA) | Quart | Each | OE 0W-16 Synthetic Motor Oil |

| OESQT (OESQT-CA) | Quart | Case of 12 | OE 0W-16 Synthetic Motor Oil |

Technical Information

Extra Information

OE 0W-16: Light and Strong

A 0W-16 viscosity motor oil may seem exotic to North American drivers, but as fuel efficiency requirements increase, it may become a common recommendation of manufacturers worldwide. Japanese engineers have long experimented with ultra-thin motor oils, and 0W-16 has been in regular use in Japan since the 90s.

The Benefits of Going Thin

Lower viscosity motor oil can increase fuel economy, and the pressure to create engines that sip less fuel has hastened the introduction of these viscosities to North America. The stated fuel mileage estimates for several 2018 vehicles were calculated with 0W-16 motor oil installed. Beyond fuel economy, lower viscosity oil can also provide excellent cold-starts in the most frigid temperatures.

OE 0W-16 Synthetic Motor Oil

The primary concern with low viscosity oil is wear protection. Like the rest of the OE line, OE 0W-16 develops a strong fluid film that keeps metal components separated and protected. Our work didn’t end with simply blending a new viscosity. OE 0W-16 Synthetic Motor Oil (OES) is formulated with unique anti-wear additives that protect critical engine parts like pistons and cams. This added protection is particularly important in the extreme environments produced by today’s smaller-displacement engines that run on lower viscosity oil.

- Provides advanced wear protection

- Improves fuel economy & maintains low emissions

- Protects pistons from low-speed pre-ignition

- Keeps engines clean

- Protects in all temperatures

- Meets the requirements of popular new vehicles like the 2018 Toyota* Camry* and the 2018 Honda* Fit*

- Recommended for use in applications that require the API SN PLUS (Resource Conserving) specification. Use only where 0W-16 is specified. Do not substitute for 0W-20 or other viscosity.

Why No API Starburst?

The International Lubricants Standardization and Approval Committee (ILSAC) has not recognized the 0W-16 viscosity for the current GF-5 oil category, which is required to display the startburst. It will likely be included in the new GF-6 category expected in 2019 or 2020. As the API “donut” indicates on the back label, OE 0W-16 is licensed for API SN Plus (Resource Conserving).

The Benefits of Going Thin

Lower viscosity motor oil can increase fuel economy, and the pressure to create engines that sip less fuel has hastened the introduction of these viscosities to North America. The stated fuel mileage estimates for several 2018 vehicles were calculated with 0W-16 motor oil installed. Beyond fuel economy, lower viscosity oil can also provide excellent cold-starts in the most frigid temperatures.

OE 0W-16 Synthetic Motor Oil

The primary concern with low viscosity oil is wear protection. Like the rest of the OE line, OE 0W-16 develops a strong fluid film that keeps metal components separated and protected. Our work didn’t end with simply blending a new viscosity. OE 0W-16 Synthetic Motor Oil (OES) is formulated with unique anti-wear additives that protect critical engine parts like pistons and cams. This added protection is particularly important in the extreme environments produced by today’s smaller-displacement engines that run on lower viscosity oil.

- Provides advanced wear protection

- Improves fuel economy & maintains low emissions

- Protects pistons from low-speed pre-ignition

- Keeps engines clean

- Protects in all temperatures

- Meets the requirements of popular new vehicles like the 2018 Toyota* Camry* and the 2018 Honda* Fit*

- Recommended for use in applications that require the API SN PLUS (Resource Conserving) specification. Use only where 0W-16 is specified. Do not substitute for 0W-20 or other viscosity.

Why No API Starburst?

The International Lubricants Standardization and Approval Committee (ILSAC) has not recognized the 0W-16 viscosity for the current GF-5 oil category, which is required to display the startburst. It will likely be included in the new GF-6 category expected in 2019 or 2020. As the API “donut” indicates on the back label, OE 0W-16 is licensed for API SN Plus (Resource Conserving).

Low-viscosity doesn’t mean low quality

As motor oil viscosity continues to decrease, base oil and additive quality become more important.

Despite uncertainty surrounding future CAFE standards, fuel economy remains the biggest driver of innovation in the auto industry. One strategy for increasing fuel economy involves reducing energy lost to friction. Using lower-viscosity lubricants, which reduce pumping losses and flow easier at startup, helps automakers accomplish this goal. Just as we've become accustomed to CW-20 oils, OW-16 oil has entered the market and is recommended for the 2018 Toyota* Camry* and Honda* Fit*. People are wondering hew much lower viscosity can go.

That’s because excessively low lubricant viscosity can reduce wear protection. Some people fear the fuel economy gains of modem low-viscosity oils aren’t worth the potential loss of wear protection. You should be familiar with the relationship between lubricant viscosity and wear protection, but it bears repeating.

Motor oil must develop a durable fluid film that separates engine components so they don’t rub together and wear out. As a rule of thumb, the higher the oil’s viscosity, the thicker the fluid film - and the better the wear protection.

That being the case, you might think it advantageous to throw out your 0W-20 motor oil and use 15W-50 instead. That’s a bad idea, and here’s why.

Modern engines are built with tighter clearances between parts than their predecessors. Let’s take the GM* 3.8L engines we test in our mechanical lab as an example. The clearances between the crankshaft journals and main bearings can be as low as .0007 inches. That’s thinner than a sheet of paper (about .004 inches).

During operation, oil continuously flows through tiny ports in the crankshaft journals to lubricate the journal/ bearing interfaces. It should form a strong, consistent oil film on which the crankshaft journals float as they spin, preventing them from touching the bearings. This is called hydrodynamic lubrication. Oil that’s too thick for the engine, however, may not flow fast enough to fill the clearances, allowing the high spots on metal surfaces to contact. This is called boundary lubrication.

In this case, using a higher viscosity oil than what’s recommended in your modern engine would lead to increased wear. Adding insult to injury, it would reduce fuel economy and increase operating temperatures as well.

Viscosity that’s too low, however, can have the opposite effect. Since viscosity is related to film thickness, low-viscosity oil may not develop an adequate fluid film to keep metal components separated, leading to wear. If bad enough, parts will eventually weld together and destroy the engine.

You can see how modern engines have put oil formulators into a bind. How do we formulate low-viscosity oils that maximize fuel economy while also providing good wear protection in today’s stressful engines?

In a word, quality.

Although oil film thickness is related to lubricant viscosity, film strength is a function of base oil and additive quality. We start with high-quality synthetic base oils that offer naturally high resistance to heat and chemical breakdown.

The challenge, however, is that lower-viscosity oils tend to be more volatile, meaning they burn off more easily when exposed to high heat. If you ever look at a motor oil’s NOACK Volatility, you’ll notice volatility tends to increase as the oil viscosity decreases. This is of particular importance since most new vehicles are equipped with turbocharged engines, which generate increased heat. High volatility can lead to excessive oil consumption, which causes the oil to thicken, making it harder to pump through the engine and reducing fuel economy. Oil that has thickened can also lead to deposits and disrupt the additive balance.

That’s why only synthetic base oils can be used to formulate a OW-16 motor oil. Conventional base oils are too volatile to meet requirements of low-viscosity oil.

Additives, too, play a vital role in low-viscosity oils. We talked about boundary lubrication earlier. When in a boundary lubrication situation, protecting against metal-to-metal contact falls on the motor oil’s anti-wear additives, more so than with higher viscosity oils. The additives form a sacrificial barrier on metal parts that absorbs contact and protects the metal surfaces.

Motor oil quality has always been important, but modem low-viscosity oils underscore the point. That’s good news for Dealers selling the best oil on the market.

Despite uncertainty surrounding future CAFE standards, fuel economy remains the biggest driver of innovation in the auto industry. One strategy for increasing fuel economy involves reducing energy lost to friction. Using lower-viscosity lubricants, which reduce pumping losses and flow easier at startup, helps automakers accomplish this goal. Just as we've become accustomed to CW-20 oils, OW-16 oil has entered the market and is recommended for the 2018 Toyota* Camry* and Honda* Fit*. People are wondering hew much lower viscosity can go.

That’s because excessively low lubricant viscosity can reduce wear protection. Some people fear the fuel economy gains of modem low-viscosity oils aren’t worth the potential loss of wear protection. You should be familiar with the relationship between lubricant viscosity and wear protection, but it bears repeating.

Motor oil must develop a durable fluid film that separates engine components so they don’t rub together and wear out. As a rule of thumb, the higher the oil’s viscosity, the thicker the fluid film - and the better the wear protection.

That being the case, you might think it advantageous to throw out your 0W-20 motor oil and use 15W-50 instead. That’s a bad idea, and here’s why.

Modern engines are built with tighter clearances between parts than their predecessors. Let’s take the GM* 3.8L engines we test in our mechanical lab as an example. The clearances between the crankshaft journals and main bearings can be as low as .0007 inches. That’s thinner than a sheet of paper (about .004 inches).

During operation, oil continuously flows through tiny ports in the crankshaft journals to lubricate the journal/ bearing interfaces. It should form a strong, consistent oil film on which the crankshaft journals float as they spin, preventing them from touching the bearings. This is called hydrodynamic lubrication. Oil that’s too thick for the engine, however, may not flow fast enough to fill the clearances, allowing the high spots on metal surfaces to contact. This is called boundary lubrication.

In this case, using a higher viscosity oil than what’s recommended in your modern engine would lead to increased wear. Adding insult to injury, it would reduce fuel economy and increase operating temperatures as well.

Viscosity that’s too low, however, can have the opposite effect. Since viscosity is related to film thickness, low-viscosity oil may not develop an adequate fluid film to keep metal components separated, leading to wear. If bad enough, parts will eventually weld together and destroy the engine.

You can see how modern engines have put oil formulators into a bind. How do we formulate low-viscosity oils that maximize fuel economy while also providing good wear protection in today’s stressful engines?

In a word, quality.

Although oil film thickness is related to lubricant viscosity, film strength is a function of base oil and additive quality. We start with high-quality synthetic base oils that offer naturally high resistance to heat and chemical breakdown.

The challenge, however, is that lower-viscosity oils tend to be more volatile, meaning they burn off more easily when exposed to high heat. If you ever look at a motor oil’s NOACK Volatility, you’ll notice volatility tends to increase as the oil viscosity decreases. This is of particular importance since most new vehicles are equipped with turbocharged engines, which generate increased heat. High volatility can lead to excessive oil consumption, which causes the oil to thicken, making it harder to pump through the engine and reducing fuel economy. Oil that has thickened can also lead to deposits and disrupt the additive balance.

That’s why only synthetic base oils can be used to formulate a OW-16 motor oil. Conventional base oils are too volatile to meet requirements of low-viscosity oil.

Additives, too, play a vital role in low-viscosity oils. We talked about boundary lubrication earlier. When in a boundary lubrication situation, protecting against metal-to-metal contact falls on the motor oil’s anti-wear additives, more so than with higher viscosity oils. The additives form a sacrificial barrier on metal parts that absorbs contact and protects the metal surfaces.

Motor oil quality has always been important, but modem low-viscosity oils underscore the point. That’s good news for Dealers selling the best oil on the market.