Product/Account Links

AMSOIL Accounts

Products

Other Products

AMSOIL Synthetic Multi-Viscosity Hydraulic Oil - ISO 22

Product Details

Synthetic Multi-Viscosity Hydraulic Oil is formulated with varnish-control technology to keep hydraulic systems cleaner for long life and reliable operation. It resists breakdown in the presence of heat while remaining fluid when cold to keep valves, pumps, servos and other components clean, protected and long-lasting. Synthetic Multi-Viscosity Hydraulic Oil is the perfect solution to the common problems that plague hydraulic applications, helping you save money.

Product Description

Maximum Cleanliness

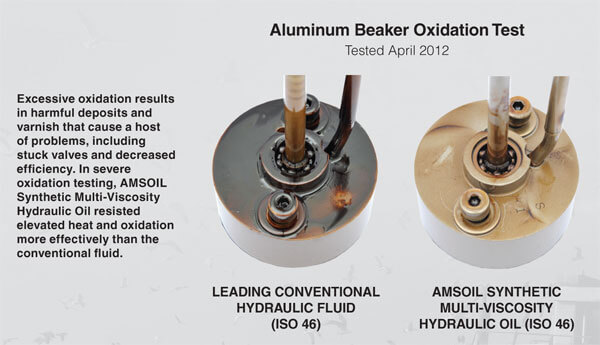

Synthetic Multi-Viscosity Hydraulic Oil is fortified with anti-varnish additives that chemically react with the building blocks of varnish, inhibiting its formation. It helps hydraulic systems remain clean for solid performance, immediate response and fewer breakdowns.

Excellent Year-Round Protection

Multi-Viscosity Hydraulic Oil's naturally heat-resistant base oils resist thermal break-down and maintain their protective viscosity, allowing formation of a strong lubricating film for excellent wear protection. Because it doesn’t contain the waxes inherent to conventional fluids, it flows more readily in cold temperatures, meaning bearings and other components receive almost immediate lubrication at start up, reducing long-term wear and instances of pressure spikes and erratic operation as a result of poor fluidity.

- All-season performance

- Maintains cleanliness

- Promotes maximum fluid life

- Resists foam

- Maximizes energy efficiency

Synthetic Multi-Viscosity Hydraulic Oil is fortified with anti-varnish additives that chemically react with the building blocks of varnish, inhibiting its formation. It helps hydraulic systems remain clean for solid performance, immediate response and fewer breakdowns.

Excellent Year-Round Protection

Multi-Viscosity Hydraulic Oil's naturally heat-resistant base oils resist thermal break-down and maintain their protective viscosity, allowing formation of a strong lubricating film for excellent wear protection. Because it doesn’t contain the waxes inherent to conventional fluids, it flows more readily in cold temperatures, meaning bearings and other components receive almost immediate lubrication at start up, reducing long-term wear and instances of pressure spikes and erratic operation as a result of poor fluidity.

- All-season performance

- Maintains cleanliness

- Promotes maximum fluid life

- Resists foam

- Maximizes energy efficiency

Fights Component Wear

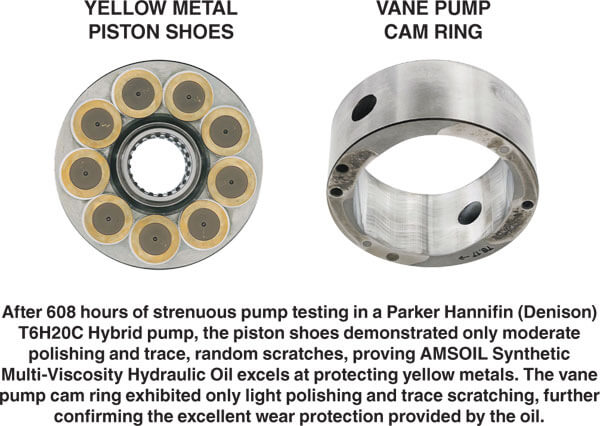

Synthetic Multi-Viscosity Hydraulic Oil features a shear-stable formulation fortified with the latest zinc-type anti-wear additives. It meets the stringent viscosity-retention requirements of Parker Hannifin* (Denison*) HF-0 and demonstrates excellent anti-wear performance and compatibility with yellow metals in standardized laboratory and pump manufacturer tests (see below). Synthetic Multi-Viscosity Hydraulic Oil demonstrates excellent protection for pumps, motors, valves and other components against wear.

Synthetic Multi-Viscosity Hydraulic Oil features a shear-stable formulation fortified with the latest zinc-type anti-wear additives. It meets the stringent viscosity-retention requirements of Parker Hannifin* (Denison*) HF-0 and demonstrates excellent anti-wear performance and compatibility with yellow metals in standardized laboratory and pump manufacturer tests (see below). Synthetic Multi-Viscosity Hydraulic Oil demonstrates excellent protection for pumps, motors, valves and other components against wear.

APPLICATIONS & SPECIFICATIONS

The correct viscosity grade of AMSOIL Synthetic Multi-Viscosity Hydraulic Oil is recommended for high- and low-pressure gear, vane and piston stationary and mobile hydraulic systems, including those with bronze metallurgy. It is recommended for all types of applications requiring the following industry and equipment specifications:

The correct viscosity grade of AMSOIL Synthetic Multi-Viscosity Hydraulic Oil is recommended for high- and low-pressure gear, vane and piston stationary and mobile hydraulic systems, including those with bronze metallurgy. It is recommended for all types of applications requiring the following industry and equipment specifications:

| Stock Code | HVG | HVH | HVI | HVJ |

|---|---|---|---|---|

| Parker Hannifin (Denison) HF-0, HF-1, HF-2 | X | X | X | |

| Vickers* I-286-S, M-2950-S | X | X | X | |

| DIN 51524 Parts 2 & 3 | X | X | X | |

| Cincinnati Milacron* P-68 | X | |||

| Cincinnati Milacron P-70 | X | |||

| Cincinnati Milacron P-69 | X |

Product Size

| Code | Package Size | Unit of Measure | Product |

|---|---|---|---|

| HVG05 (HVG05-EA) | 5-Gallon Pail | Each | Synthetic Multi-Viscosity Hydraulic Oil - ISO 22 |

| HVG55 (HVG55-EA) | 55-Gallon Drum | Each | Synthetic Multi-Viscosity Hydraulic Oil - ISO 22 |

| HVG27 (HVG27-EA) | 275-Gallon Tote | Each | Synthetic Multi-Viscosity Hydraulic Oil - ISO 22 |

Technical Information

Extra Information

Three of the most common problems plaguing hydraulic oil systems:

Heat degradation

Increased fluid temperatures can be the result of the system’s inability to dissipate heat. In most systems, heat within the fluid dissipates through the fluid in the reservoir and a heat ex-changer. Heat can cause the fluid to thin, which prevents proper lubrication and may cause pump leaks, reducing pump efficiency and system performance. Further increases in temperature cause the fluid to oxidize (or, essentially, vaporize), which thickens the fluid and creates varnish and deposits. Fluid thickening further impedes its ability to cool and lubricate components and may cause deposits to form on components, restricting fluid flow.

Air contamination

Noise is usually related to air entering the system, which leads to aeration or cavitation. When air bubbles contaminate the fluid, it’s referred to as aeration and results in banging or knocking noises due to the compression and decompression of the air as it moves through the system. Air also causes wear due to the implosion of air bubbles under the immense system pressure. Erratic actuator movement is also often the result of aeration. When air is compressed in the system it causes increases in temperature, which degrades the hydraulic fluid and overheats the seals. Air can also cause damage due to lack of lubrication.

Cavitation can also be a source of noise and erratic actuation. Cavitation is the result of fluid vapor or air cavities within the fluid, which implode when compressed, causing a knocking noise. Cavitation causes wear, damaging components and contaminating the fluid with metal particles, which in extreme cases can cause mechanical failure.

Water contamination

Hydraulic fluid that has a milky appearance is a clear indication of water contamination. One source is condensation buildup on the walls of the fluid reservoir as a result of temperature changes from warm days to cool nights. Water contamination can also corrode the pump and other critical components, which can shorten component life. Water can also freeze, causing a host of performance and wear-related issues. Periodic fluid changes and draining of the water from the reservoir ensure water removal from the system.

Increased fluid temperatures can be the result of the system’s inability to dissipate heat. In most systems, heat within the fluid dissipates through the fluid in the reservoir and a heat ex-changer. Heat can cause the fluid to thin, which prevents proper lubrication and may cause pump leaks, reducing pump efficiency and system performance. Further increases in temperature cause the fluid to oxidize (or, essentially, vaporize), which thickens the fluid and creates varnish and deposits. Fluid thickening further impedes its ability to cool and lubricate components and may cause deposits to form on components, restricting fluid flow.

Air contamination

Noise is usually related to air entering the system, which leads to aeration or cavitation. When air bubbles contaminate the fluid, it’s referred to as aeration and results in banging or knocking noises due to the compression and decompression of the air as it moves through the system. Air also causes wear due to the implosion of air bubbles under the immense system pressure. Erratic actuator movement is also often the result of aeration. When air is compressed in the system it causes increases in temperature, which degrades the hydraulic fluid and overheats the seals. Air can also cause damage due to lack of lubrication.

Cavitation can also be a source of noise and erratic actuation. Cavitation is the result of fluid vapor or air cavities within the fluid, which implode when compressed, causing a knocking noise. Cavitation causes wear, damaging components and contaminating the fluid with metal particles, which in extreme cases can cause mechanical failure.

Water contamination

Hydraulic fluid that has a milky appearance is a clear indication of water contamination. One source is condensation buildup on the walls of the fluid reservoir as a result of temperature changes from warm days to cool nights. Water contamination can also corrode the pump and other critical components, which can shorten component life. Water can also freeze, causing a host of performance and wear-related issues. Periodic fluid changes and draining of the water from the reservoir ensure water removal from the system.